One-stop Solution for Mechanical Parts Manufacturing

- We specialize in the manufacturing of castings, forgings, flanges, and machined parts, providing comprehensive solutions from R&D and production to sales and technical support.

- 18 Years’ Machining Experience

- Multiple Machining Processing Techniques

- Low Tolerance

- Rapid Prototyping

- Custom Solutions Available

High-precision Hot Forging Solutions

- We specialize in forging wheels, flanges, gears, shafts, and complex custom-shaped parts for diverse industrial applications.

- Our tailored processes ensure optimal performance and cost-effective solutions for every customer need.

Comprehensive Castings & Pipeline Solutions

- We provide castings, 180-degree elbows, and butt welded fittings made from stainless steel, carbon steel, aluminum, and various special alloys.

- Using Investment, gravity, and die casting methods, we ensure the best process and solution for every product.

Our Main Machining Capabilities

Forging

Uses compressive force to shape heated metal, improving strength, grain structure, and mechanical properties for demanding industrial applications.

- Enhances strength and fatigue resistance for loads.

- Produces excellent grain structure and strength.

- Reduces waste versus solid billet machining.

- Ideal for energy, aerospace, high-stress use.

Casting

Involves pouring molten metal into molds, enabling complex shapes, diverse materials, and economical mass production of precision components.

- Forms complex shapes with cavities easily.

- Allows diverse material and alloy use.

- Affordable solution for mass production needs.

- Ensures precise sizing and smooth finishes.

Post Machining

After forging or casting, we perform CNC machining, surface treatment, and other finishing processes to ensure precision, quality, and performance.

- Achieves high precision and surface finish.

- Adds threads, holes, and grooves.

- Supports custom assembly requirements.

- Includes CNC, treatment, and inspection.

Industries We Service

We provide specialized solutions across industries, offering forgings, special flanges, castings, and mechanical components. Explore the sectors we support.

Our Projects

Hot Forgings

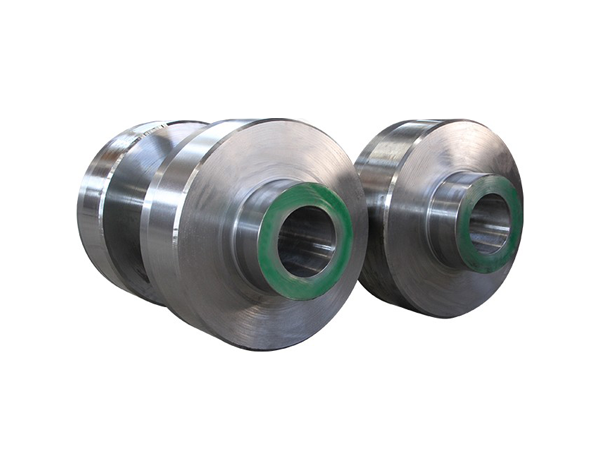

Rolled Rings

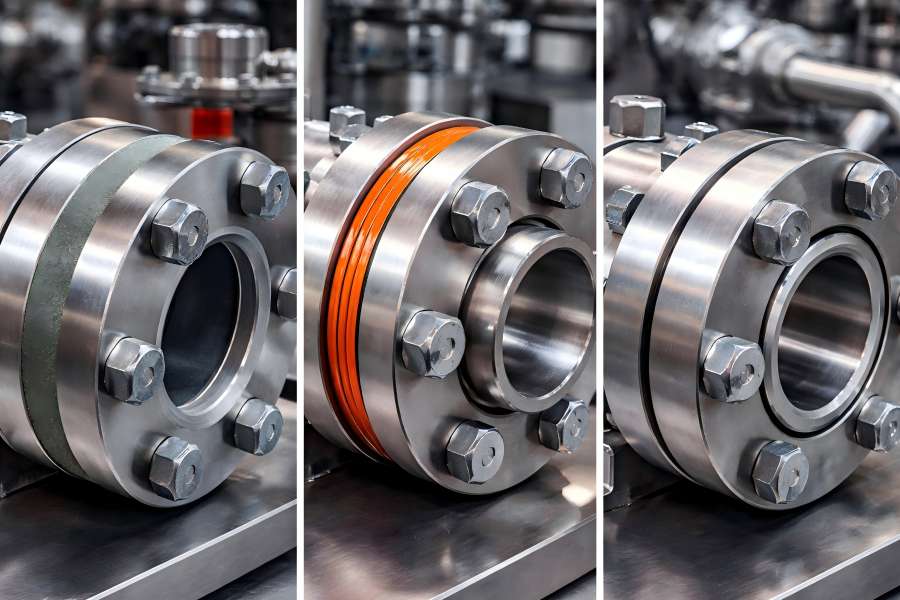

Special Flanges

Standard Flanges

Pipeline Connection

Precision Castings

- Custom sizes based on client drawings.

- Supports open and closed die forging.

- Meets GB and JIS standards.

- Certified by ISO9001, PED, SGS.

- Made from premium-grade ingot steel.

- Using EAF, LF, VD, ingot process.

- Forged through open or die forging.

- Tolerance meets ±0.01mm precision.

- Supports carbon, alloy, stainless steels.

- Conforms to ASTM, DIN, EN standards.

- Certified by BV, UL, CE, and ISO.

- Suitable for heavy industrial applications.

- Custom sizes and shapes available.

- Surface finish achieves Ra0.4 roughness.

- Performs in presses and mining crushers.

- Used in cement, sugar, paper industries.

- Made from steel and alloy steel.

- Process includes forging and machining.

- Maximum diameter reaches 8000 mm.

- Weight capacity up to 30 tons.

- Made from standard bearing steel.

- Forged and fully machined precisely.

- Dimensions customized to client request.

- Used in marine, energy, mining sectors.

- Made from steel, alloy, stainless materials.

- Diameter reaches up to 8000 mm.

- Maximum length supported is 1200 mm.

- Weight capacity up to 7000 kg.

- Made from steel and alloy steel.

- Supports custom dimensions designs.

- Forged and heat treated for strength.

- Includes rough and final machining steps.

- Made from steel and alloy steel.

- Process includes forging and machining.

- Maximum diameter reaches 8000 mm.

- Weight capacity up to 30 tons.

- Made from Cu-Ni, Ti-Ni, Fe-Ni alloys.

- Withstands 650 ℃ to 1000 ℃.

- Superior strength and resists corrosion.

- Suits aerospace and energy systems.

- Made from Monel 400, K500, 600.

- Excellent toughness and corrosion resistance.

- Used in exchangers, towers, condensers.

- Ideal for nuclear and heat treatment.

- Diameter range 50mm to 1200mm.

- Maximum weight does not exceed 80kgs.

- Complex shapes easily manufactured.

- Tolerance strictly within 0.05mm.

- Available in 304, 316L, 321, 347H.

- Uses metal ring for secure sealing.

- Fits weld neck, slip-on, blind flanges.

- Ideal for high-pressure piping systems.

- No central hole for full sealing.

- Multiple sealing surface types available.

- Forged, cast, or cut for precision.

- Size spans from 15mm to 6000mm.

- Forged from stainless steel material.

- Size range covers 1/2" to 72".

- Withstands 150lb to 2500lb pressure.

- Butt welded for strong pipe connection.

- Made from carbon and stainless steel.

- Available with neck or without neck.

- Size range from 1/2" to 72".

- Pressure class up to 2500# supported.

- Made from C276, Incoloy800 series.

- Available in sizes 2" to 24".

- High strength and oxidation resistance.

- Suitable for nuclear and aerospace uses.

- Made from Monel 400, K500, 600.

- High toughness and corrosion resistance.

- Ends offered in bevel or plain.

- Used in chemical, power, nuclear industries.

- Made from S31803, S32205, S32750.

- Resists thermal cracking during fabrication.

- Surface treated with sand or ball blast.

- Used in petrochemical and wastewater systems.

- Excellent corrosion and chemical resistance properties.

- Offers sizes from 2" to 12".

- Sandblasted or varnished for rust protection.

- Compatible with global industrial piping standards.

- Made from stainless, carbon, duplex steels.

- Customized by shape, weight, and application.

- Machining tolerance up to ±0.009mm.

- Surface roughness Ra1.6 to Ra3.2.

- Made from S32750, S31803, S31500 alloys.

- Weight range from 1g to 99kg.

- Minimum thickness reaches 0.5mm.

- Applied in marine and chemical industries.

- Multiple material options for selection.

- Forms complex shapes with fine details.

- Little need for secondary machining.

- Used in textile, hardware, marine sectors.

- Common materials include ADC6, ADC12.

- Corrosion resistant and easy to weld.

- Enables thin walls and complex shapes.

- Widely used in power machinery production.

About Us

Established in 2008, Boberry Material Co., Ltd is a family-owned enterprise dedicated to the research and manufacturing of mechanical components.

- With over a decade of experience, we offer tailored process solutions to ensure optimal cost and performance across forgings, special flanges, castings, and precision parts.

- Serving industries such as metallurgy, oil & gas, chemical, energy, shipbuilding, and machinery.

We maintain certified quality standards and provide value-added services to clients worldwide, especially in Europe and North America.

Why Choose Us?

End-to-End Manufacturing Expertise

From raw material processing to final assembly, our full production line ensures reliable quality and cost control.

Certified Quality & Engineering Excellence

ISO9001 and TUV certifications, modern testing facilities, and over 60 senior engineers ensure world-class precision.

Tailored Technical Solutions

We help clients optimize designs and processes for high-precision, complex components—even offering customized assembly services.

Global Trust, Local Support

With subsidiaries in Germany, Hong Kong, and multiple China bases, we deliver both international reliability and responsive local service.

Tailored Solutions with Timely Delivery

We offer custom forged and cast mechanical parts with on-time delivery for small to large orders.

Checkout Latest Articles

Read More

Read More

Read More

Read More

Read More

Read More